Related Products & Systems on Other Pages on This Website

Tool & Industrial Equipment Tracking System

Employee & Attendance Access Control System

Work In Process WIP Asset Tracking System

People Tracking System for Manufacturing Facilities

GAO RFID Inventory Management System Using Handheld RFID Reader

BLE | Bluetooth Low Energy | BLE Gateways & Beacons – GAO RFID

RFID Readers | Buy RFID Readers | RFID Reader Writers – GAO RFID

RFID Tags | Buy RFID Tags – GAO RFID

Rugged RFID Tags | GAO RFID Inc.

Tamper Proof RFID Tags | Security RFID Tags – GAO RFID

On Metal RFID Tags – All Types

High Temperature RFID Tags – GAO RFID

Overview

Steel product manufacturing from purchased steel involves procuring raw steel materials, inspecting their quality, cutting and forming them into desired shapes, potentially undergoing heat treatment and surface finishing, ensuring quality through rigorous checks, packaging, and finally distributing the finished products to customers, while also providing necessary customer support. This process spans various industries and results in a diverse range of steel products used in construction, manufacturing, and other sectors.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in Steel product manufacturing from purchased Industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as cutting and forming machinery like shearing and laser cutting machines, machining tools such as CNC mills and lathes, heat treatment equipment like furnaces and induction heaters, surface treatment tools including galvanizing baths and paint booths, quality control devices like CMMs and NDT equipment, material handling mechanisms like cranes and conveyors, packaging machines, safety gear, utilities like generators and compressed air systems, control systems like PLCs and HMIs, and testing equipment like spectrometers and tensile testing machines, all of which collectively facilitate the transformation of raw steel into finished products.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed steel product manufacturing from purchased steel industry. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for steel product manufacturing from purchased steel industry

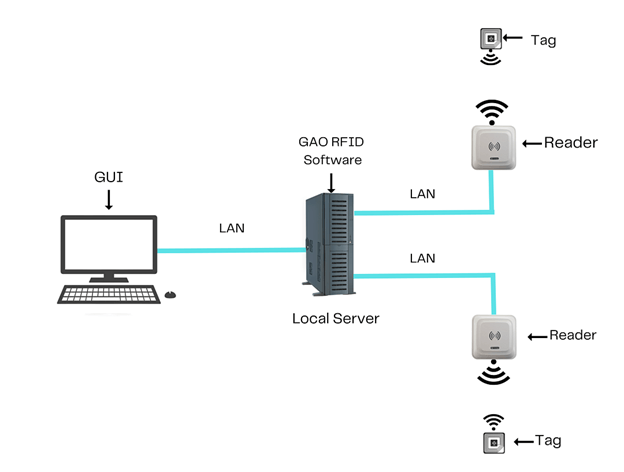

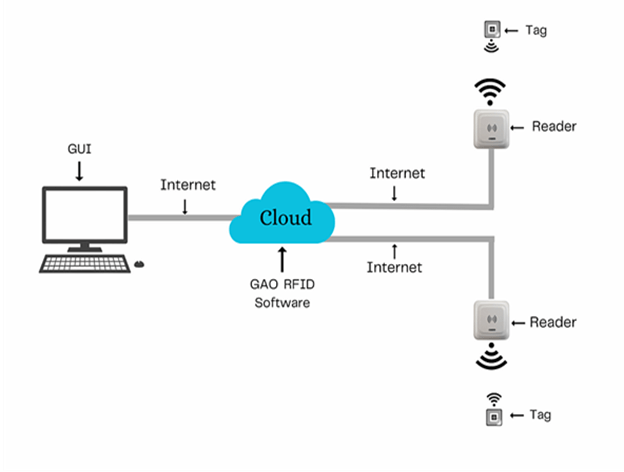

To satisfy its customers, GAO’s RFID or RFID Systems for steel product manufacturing from purchased steel product are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premise, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for steel product manufacturing from purchased steel industry software running on a local server.

The above illustrates GAO system for steek product manufacturing from purchased steel industry with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in steel product manufacturing from purchased steel industry:

- Inventory Management: Utilizing our RFID tags can be attached to raw steel materials, allowing for accurate and real-time tracking of inventory levels. This helps streamline the ordering process, reduces stockouts, and optimizes material usage.

- Work-in-Progress Tracking: Utilizing our RFID tags on workpieces enable real-time tracking of each stage of manufacturing, providing insights into production progress, potential bottlenecks, and overall process efficiency.

- Quality Control: GAO’s RFID can be used to associate quality data with specific steel products, enabling easy retrieval of information regarding material specifications, inspections, tests, and certifications.

- Tool and Equipment Tracking: Our RFID tags on tools and equipment ensure that the right tools are used for each task and that they are returned after use, minimizing delays and enhancing productivity.

- Maintenance and Calibration: Our RFID tags can be employed to schedule and monitor maintenance and calibration of equipment and machinery, improving reliability and minimizing downtime.

- Traceability and Compliance: RFID facilitates the tracing of each steel product’s journey through the manufacturing process, enhancing the ability to meet regulatory requirements and respond to quality issues or recalls.

- Supply Chain Visibility: Our RFID enables real-time monitoring of shipments, ensuring that purchased steel materials are tracked from supplier to manufacturer, thereby improving supply chain transparency.

- Automated Data Capture: Our RFID eliminates the need for manual data entry by automating the capture of information, reducing errors and saving time.

- Access Control: Our RFID technology can manage access to restricted areas within the manufacturing facility, enhancing security and preventing unauthorized personnel from entering sensitive areas.

- Labor Tracking: Our RFID tags can be integrated into employee badges for tracking attendance, monitoring work hours, and providing insights into labor utilization.

- Real-Time Alerts and Notifications: GAO’s RFID-enabled systems can send alerts when certain conditions are met, such as when inventory levels are low or when a process is completed.

- Container and Asset Tracking: Our RFID tags on containers, pallets, and assets (like molds or specialized tools) allow for quick identification, reducing the risk of lost or misplaced items.

- Energy Management: Our RFID can be used to control energy usage by automatically turning off equipment when not in use or adjusting settings based on occupancy.

- Integration with ERP Systems: Our RFID data can be seamlessly integrated with enterprise resource planning (ERP) systems, providing accurate and up-to-date information for decision-making.

- Product Authentication: Our RFID technology can help in verifying the authenticity of steel products and preventing counterfeiting.

GAO’s drone technologies find the following applications in the steel product manufacturing from purchased steel industry:

- Site Surveys and Inspections: Utilizing GAO’s Drones can conduct aerial surveys of manufacturing facilities, providing a comprehensive view of the layout and infrastructure. They can also inspect hard-to-reach areas, such as tall structures or confined spaces, for maintenance or quality checks.

- Inventory Management: Our Drones equipped with cameras and sensors can rapidly scan and count large quantities of purchased steel materials in storage yards, improving inventory accuracy and reducing manual labor.

- Construction Progress Monitoring: In our steel construction projects, drones can capture high-resolution images and videos of ongoing work, offering project managers an up-to-date visual record of construction progress and identifying potential issues.

- Quality Control and Defect Detection: GAO’s Drones equipped with high-resolution cameras and thermal imaging can identify defects, inconsistencies, or structural issues in steel products during and after manufacturing, helping ensure quality standards are met.

- Safety Inspections: GAO’s Drones can assess potentially hazardous areas, such as high platforms or areas with toxic substances, without exposing workers to risks, thereby enhancing workplace safety.

- Environmental Monitoring: Our Drones can monitor emissions, waste disposal, and compliance with environmental regulations, helping companies maintain sustainability and adhere to environmental standards.

- Facility Security: Our Drones equipped with cameras and sensors can monitor the perimeter of manufacturing facilities, detecting unauthorized access, potential security breaches, or unusual activities.

- 3D Mapping and Modeling: Our Drones can create accurate 3D models and maps of manufacturing sites, aiding in the planning of layouts, expansions, and modifications.

- Supply Chain Management: Our Drones can be used to monitor the movement of purchased steel materials from suppliers to the manufacturing facility, enhancing supply chain visibility and reducing delays.

- Infrastructure Maintenance: Our Drones can perform routine maintenance inspections of facilities and equipment, identifying issues early to prevent costly breakdowns or disruptions.

- Training and Documentation: Our Drones can capture training videos, safety demonstrations, and instructional content for employees, enhancing training programs and ensuring consistent information dissemination.

- Emergency Response: In case of accidents or emergencies, drones can quickly assess the situation, provide real-time information to responders, and assist in coordinating rescue efforts.

- Geospatial Analysis: GAO’s Drones equipped with specialized sensors can gather geospatial data, aiding in land use planning, site selection, and resource management.

- Precision Agriculture (if applicable): For steel products used in agriculture, drones can help optimize crop management by monitoring soil health, irrigation, and pest control.

- Marketing and Promotion: Drones can capture captivating aerial footage and images of manufacturing facilities, showcasing the scale and capabilities of the steel product manufacturing process.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the steel product manufacturing from purchased steel industry:

- Remote Monitoring: Utilizing GAO’s IoT sensors can be deployed on equipment, machinery, and processes to monitor their performance in real time, enabling proactive maintenance and reducing downtime.

- Predictive Maintenance: Our IoT-enabled sensors collect data on the condition of machinery, predicting when maintenance is needed based on factors like temperature, vibration, and usage patterns, optimizing maintenance schedules and preventing costly breakdowns.

- Energy Management: IoT devices are we monitor energy consumption across the manufacturing facility, identifying opportunities for energy efficiency improvements and cost savings.

- Supply Chain Visibility: GAO’s IoT sensors can track the movement of purchased steel materials from suppliers to manufacturing sites, providing real-time insights into shipment status and potential delays.

- Quality Control: GAO’s IoT devices can monitor parameters such as temperature, humidity, and pressure during the manufacturing process, ensuring that steel products meet quality standards.

- Process Optimization: GAO’s IoT-enabled analytics can identify inefficiencies in manufacturing processes and provide data-driven insights to optimize production flows and resource utilization.

- Real-Time Data Analysis: GAO’s IoT platforms can collect and analyze data from various sources, providing actionable insights to operators and decision-makers for informed process adjustments.

- Traceability and Compliance: Our IoT solutions can track the journey of steel products through the manufacturing process, aiding in regulatory compliance and quality assurance.

- Asset Tracking: GAO’s IoT-enabled tags can be attached to assets such as tools, molds, and equipment, allowing for easy tracking and efficient utilization.

- Environmental Monitoring: Our IoT sensors can monitor air and water quality within the manufacturing facility, ensuring compliance with environmental regulations and maintaining a safe work environment.

- Remote Control and Automation: Our IoT-enabled devices allow for remote control of machinery and equipment, enabling operators to adjust settings and respond to issues without being physically present.

- Collaborative Robotics (Cobots): Our IoT-enabled cobots can work alongside human workers, performing tasks that require precision and strength, while also communicating with other machines in the production line.

- Waste Reduction: Our IoT data we can help identify areas of waste in the production process, leading to more efficient resource utilization and reduced material wastage.

- Data-Driven Decision-Making: Our IoT-generated data can be used to make informed decisions related to production planning, inventory management, and overall operational strategies.

- Worker Safety: Our IoT sensors can monitor the work environment for factors like temperature, humidity, and gas levels, ensuring optimal conditions for worker safety.

- Remote Troubleshooting: Our IoT-enabled devices can transmit real-time data to experts who can diagnose issues remotely, reducing the need for on-site visits and minimizing downtime.

GAO’s Assists Clients with Standards, Mandates & Regulations of steel product manufacturing from purchased steel industry

GAO RFID Inc. has developed its products and systems in compliance with industry standards and mandates. GAO has assisted our customers in steel product manufacturing from purchased steel industry To deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with applicable industry standards, U.S. government regulations and Canadian government regulations such as:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000-6C (EPC Gen2)

- ISO 15693

- ISO 14443

- ISO 28560

- ISO 17363

- ISO 22915

- ISO/IEC 24730 (RTLS)

- EPCIS (EPC Information Services)

- Bluetooth 4.0 (BLE)

- Bluetooth 4.2

- Bluetooth 5

- Bluetooth Mesh

- GATT (Generic Attribute Profile)

- iBeacon

- Eddystone

- BLE Profiles

- Industrial IoT (IIoT) Standards

- MQTT (Message Queuing Telemetry Transport)

- CoAP (Constrained Application Protocol)

- HTTP/HTTPS

- OMA LwM2M (Open Mobile Alliance Lightweight M2M)

- OneM2M

- DDS (Data Distribution Service)

- OPC UA (Unified Architecture)

- Thread

- Zigbee

- LoRaWAN (Long Range Wide Area Network)

- Sigfox

- IoT Security Standards (IoTSEC)

- EdgeX Foundry

- FIWARE

- ISO/IEC JTC 1/SC 41 (IoT Standards Subcommittee)

US.Government Regulations

- Occupational Safety and Health Administration (OSHA) Regulations

- Clean Air Act Regulations

- Clean Water Act Regulations

- Resource Conservation and Recovery Act (RCRA) Regulations

- Toxic Substances Control Act (TSCA) Regulations

- National Emission Standards for Hazardous Air Pollutants (NESHAP)

- Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) Regulations

- Department of Transportation (DOT) Hazardous Materials Regulations

- Environmental Protection Agency (EPA) Emission Standards

- Mine Safety and Health Administration (MSHA) Regulations

- National Institute for Occupational Safety and Health (NIOSH) Standards

- Federal Motor Carrier Safety Administration (FMCSA) Regulations

Canadian Government Regulations

- Canadian Environmental Protection Act (CEPA) Regulations

- Canadian Environmental Assessment Act (CEAA) Regulations

- Transportation of Dangerous Goods Act Regulations

- Canada Labour Code (Part II) Regulations

- Hazardous Products Regulations

- National Energy Board Act Regulations

- Fisheries Act Regulations

- Export and Import Permits Act Regulations

- Controlled Goods Program Regulations

- Canadian Standards Association (CSA) Standards

- Canadian Nuclear Safety Commission (CNSC) Regulations

- Health Canada’s Workplace Hazardous Materials Information System (WHMIS) Regulations

GAO’s Software Provides API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in steel product manufacturing from purchased steel industry such as:

Personnel Management:

- Workforce Scheduling and Shift Management

- Employee Attendance Tracking

- Health and Safety Monitoring

- Training and Certification Tracking

- Performance Evaluation and Appraisals

Equipment Management:

- Equipment Maintenance Scheduling

- Condition Monitoring and Predictive Maintenance

- Asset Tracking and Inventory Management

- Equipment Calibration and Certification Management

- Remote Equipment Diagnostics and Troubleshooting

Access Control:

- Secure Entry and Exit Control

- Visitor Management and Authorization

- Access to Restricted Areas Monitoring

- Integration with Employee Identification (ID) Cards

- Real-Time Alerts for Unauthorized Access

Warehouse Management:

- RFID Tagging and Tracking of Raw Materials and Products

- Inventory Optimization and Reorder Point Management

- Material Movement Tracking Within the Facility

- Real-Time Stock-Level Monitoring

- Order Fulfillment and Shipping Management

Supply Chain Management:

- Supplier Relationship Management

- Real-Time Shipment Tracking

- Demand Forecasting and Order Management

- Supplier Compliance and Quality Assurance

- Collaboration with Suppliers and Distributors

Others Application:

- Real-Time Process Monitoring and Control

- Quality Control and Defect Detection

- Production Flow Analysis and Optimization

- Downtime Reduction and Efficiency Enhancement

- Energy Consumption Monitoring and Reduction

- Data Collection and Analysis for Process Improvement

- Key Performance Indicator (KPI) Monitoring

- Customizable Dashboards and Reports

- Root Cause Analysis for Issues and Delays

- Business Intelligence for Informed Decision-Making

- Monitoring Emissions and Waste Management

- Compliance with Health and Safety Regulations

- Documentation of Regulatory Compliance Activities

- Reporting and Documentation for Audits

- Integration of IoT Devices and Sensors

- Real-Time Data Exchange Between Machines and Systems

- Smart Factory Automation and Robotics

- Cloud-Based Manufacturing Execution Systems (MES)

- Data-Driven Insights for Continuous Improvement

GAO has enabled its customers to make use of some of the leading software and cloud services in steel product manufacturing from purchased steel industry. Below are some of popular software and cloud services in steel product manufacturing from purchased steel industry

In the steel product manufacturing industry, leading commercial software for personnel management includes SAP SuccessFactors for comprehensive HR solutions, Workday for cloud-based HR and payroll management, Oracle HCM Cloud for talent and workforce management, ADP Workforce Now for integrated HR and payroll, and Kronos Workforce Central for workforce management. For equipment management, prominent solutions comprise IBM Maximo for asset maintenance and tracking, Infor EAM for enterprise asset management, Fiix CMMS for maintenance scheduling, EZOfficeInventory for asset tracking, and UpKeep for mobile-centric maintenance management, offering streamlined processes and enhanced operational efficiency.

GAO has worked with some of the leading technology companies in steel product manufacturing from purchased steel in to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in steel product manufacturing from purchased steel Leading information technology companies providing solutions for the steel product manufacturing industry from purchased steel include SAP, Oracle, IBM, Siemens, Microsoft, ABB, Rockwell Automation, Schneider Electric, Hexagon, and PTC. These companies offer a range of software and services, such as ERP, automation, IoT, and cloud solutions, tailored to optimize processes, enhance efficiency, and support decision-making in steel manufacturing operations.

Prominent electronic technology companies catering to the steel product manufacturing industry from purchased steel include Siemens, ABB, Rockwell Automation, Schneider Electric, Honeywell, Mitsubishi Electric, Yokogawa Electric, FANUC, Omron Corporation, and Endress+Hauser. These companies offer a range of electronic solutions, encompassing automation, control systems, robotics, energy management, and process control, all tailored to optimize steel manufacturing processes, enhance operational efficiency, and improve overall performance.

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

Below are some RFID application cases in steel product manufacturing from purchased steel industry.

- Raw Material Tracking RFID tags on purchased steel materials track their journey from suppliers to the facility, improving material availability and production planning.

- Work-in-Progress Tracking RFID tags on steel products enable real-time tracking of their manufacturing stages, reducing bottlenecks and improving scheduling.

- Quality Control and Traceability RFID associates quality data with steel products, ensuring accurate recording of inspections and tests for traceability.

- Tool and Equipment Management RFID tags on tools track their usage, ensuring proper tool selection and facilitating maintenance.

- Maintenance and Calibration RFID schedules and monitors equipment maintenance, minimizing downtime and production delays.

- Inventory Management RFID tags on steel products enable real-time inventory tracking, optimizing stock management and reducing waste.

- Shipping and Distribution RFID on finished products improves shipping accuracy and order fulfillment efficiency.

- Supply Chain Visibility RFID monitors steel product movement, enhancing supply chain transparency.

- Automated Data Capture RFID automates data capture, reducing errors and accelerating information processing.

- Access Control and Worker Safety RFID access control systems enhance security and safety by restricting area access.

- Many applications of RFID by GAO can be found here

Case Studies of IoT Applications

Below are some IoT application cases in steel product manufacturing from purchased steel industry.

- Nucor is a leading steel manufacturer in the USA. They have been known to implement IoT solutions to optimize their steel manufacturing processes. For instance, they might have utilized IoT sensors to monitor equipment health, track inventory levels, and improve energy efficiency.

- SDI is another prominent steel producer that could have adopted IoT technologies to enhance their manufacturing operations. IoT sensors could be employed to gather data on temperature, pressure, and other parameters during the steel production process, leading to better quality control.

- U.S. Steel might have explored IoT applications to improve safety and productivity in their steel manufacturing plants. They could have integrated IoT devices for real-time monitoring of worker activities, equipment status, and environmental conditions.

- AK Steel, before its acquisition by Cleveland-Cliffs, might have embraced IoT for predictive maintenance of machinery. By analyzing data from sensors on critical equipment, they could have anticipated potential failures and scheduled maintenance before breakdowns occurred.

- ArcelorMittal, one of the world’s largest steel producers, likely examined IoT solutions for optimizing the entire steel production lifecycle. This could involve utilizing IoT devices for tracking raw material shipments, monitoring energy consumption, and improving supply chain visibility.

- Big River Steel, a newer player in the industry, could have implemented IoT technologies for process automation. They might have integrated sensors and data analytics to streamline operations and minimize manual interventions.

- As a manufacturer of seamless and welded steel tubular products, TMK IPSCO might have leveraged IoT devices to monitor the production of specialized steel pipes. IoT data could assist in maintaining consistent quality and adherence to specifications.

- Gerdau Ameristeel might have looked into IoT-enabled solutions for asset tracking and optimization. Sensors could be applied to track the movement of steel products within their facilities and across the supply chain.

- TimkenSteel, known for producing high-performance steel products, might have adopted IoT solutions for real-time quality monitoring. Sensors could provide data on material properties during the manufacturing process to ensure product consistency.

- EVRAZ, a producer of steel and other materials, could have integrated IoT sensors to monitor equipment efficiency and energy consumption. This could lead to improved resource management and cost savings.

- Case Studies of Drone Applications

Below are some drone application cases in steel product manufacturing from purchased steel industry.

- Drones could be used to conduct regular inventory checks in steel manufacturing facilities. By flying over large storage areas, drones can quickly capture images and data, helping to track raw materials and finished products. They could also be equipped with cameras and sensors to inspect inventory for damage or defects.

- Drones could be employed for security purposes in steel manufacturing plants. They can patrol the premises, monitor restricted areas, and provide real-time video feeds to security personnel, helping to prevent theft, vandalism, and unauthorized access.

- Drones equipped with sensors and cameras could be used for maintenance inspections of equipment and structures. They can provide a bird’s-eye view of machinery, identifying potential issues and helping maintenance teams make informed decisions about repairs or replacements.

- Drones could assist in monitoring environmental conditions in and around steel manufacturing facilities. They can collect data on air quality, noise levels, and emissions, helping companies ensure compliance with environmental regulations.

- Drones can access areas that are difficult for humans to reach safely. In steel manufacturing, drones could inspect elevated structures, bridges, and high-risk zones to identify safety hazards and ensure compliance with safety protocols.

- For steel construction projects, drones could provide ongoing visual updates on progress. They can capture images and videos of construction sites, track project milestones, and help project managers monitor work quality and adherence to timelines.

- Drones equipped with cameras and sensors could be used for quality control during the manufacturing process. They could inspect steel products for dimensional accuracy, surface defects, and other quality-related parameters.

- Drones could help monitor the movement of raw materials and finished products within and between manufacturing facilities. They can track shipments, verify inventory levels, and optimize logistical operations.

- Some steel manufacturing facilities might be located in remote or challenging-to-reach areas. Drones can provide a cost-effective way to assess such sites, gather data, and plan for infrastructure improvements.

- In the event of emergencies such as fires or chemical spills, drones could provide real-time aerial footage to emergency response teams, enabling them to assess the situation and plan their actions more effectively.

GAO RFID Systems & Hardware for steel product manufacturing from purchased steel industry

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including steel product manufacturing from purchased steel

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including steel product manufacturing from purchased steel.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including steel product manufacturing from purchased steel:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including steel product manufacturing from purchased steel:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including steel product manufacturing from purchased steel:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including steel product manufacturing from purchased steel industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- Find Your 860-960 MHz RFID Modules

- Find Your 13-56 MHz High Frequency RFID Modules

- Find Your 125 KHz Low Frequency RFID Modules

In collaboration with its sister company GAO Tek Inc, a wide selection of high quality drones are offered:

The RFID systems by GAO are highly popular for clients in steel product manufacturing from purchased steel

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include

In steel product manufacturing from purchased steel, a range of specialized equipment is employed. These include blast furnaces for iron extraction, electric arc furnaces and basic oxygen furnaces for steel production, and continuous casting machines for shaping molten steel into solid forms. Rolling mills and hot strip mills shape steel into various products, while heat treatment furnaces modify its properties. Pickling and galvanizing lines prepare and protect surfaces, and cutting machines, welding equipment, and CNC machining centers shape and join components. Coating and painting equipment apply protective layers, and material handling tools transport goods. Quality control and testing equipment ensure products meet standards. The equipment utilized varies based on product type, processes, and facility size. People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for steel product manufacturing from purchased steel industry: and for various industries in all metropolitans in North America, particularly the U.S., Canada and Mexico, and Europe: https://gaorfid.com/services.

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in steel product manufacturing from purchased steel industry: we have worked with to serve our joint customers:

- Industry Associations and Directories

- Online Search and Directories

- Trade Shows and Conferences

- Industry Publications and Magazines

- Contact Industry Experts and Consultants

- LinkedIn and Professional Networks

- Company Websites of Steel Manufacturers

- IT Consulting Firms

- Due Diligence and Verification

- Industry Associations and Directories

- Online Search and Directories

- Trade Shows and Conferences

- Industry Publications and Websites

- LinkedIn and Professional Networks

- Company Websites of Canadian Steel Manufacturers

- Consulting with Industry Experts and Advisors

- IT Consulting Firms Specializing in Manufacturing

- Due Diligence and Selection Process

GAO Has Served steel product manufacturing from purchased steel Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in steel product manufacturing from purchased steel Industry to achieve success in Digital Transformation, Predictive Maintenance, Big Data, Cloud Computing, Blockchain, Smart Factory, Edge Computing, Cybersecurity in Manufacturing, Distributed Ledger Technology, Reshoring, Agile Manufacturing, Just-in-Time (JIT) Manufacturing, Just-in-Time (JIT) Manufacturing, Cyber-Physical Systems (CPS), Robotics and Automation, Energy Management, Smart Sensors, Lean Manufacturing, Collaborative Robots (Cobots), Materials Science Innovations, Digital Transformation, Predictive Maintenance.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in steel product manufacturing from purchased steel industry, including many in its various divisions such as encompasses diverse divisions including,

- Flat Products and Long Products Manufacturing: This division encompasses the production of both flat and long steel products, including sheets, plates, and various forms of bars and rods. Flat products are used in applications like automotive manufacturing and construction, while long products are often utilized in structures like buildings, bridges, and machinery.

- Pipe and Tube Production: Pipe and tube production involves the manufacturing of pipes and tubes used in diverse industries such as oil and gas, construction, and infrastructure development. These products serve as conduits for liquids, gases, and other materials.

- Structural Steel Fabrication: Structural steel fabrication focuses on producing steel components used in building frameworks, bridges, and other large structures. These fabricated elements provide strength and stability to various constructions.

- Casting and Forging: Casting and forging processes are used to create metal components with desired shapes and properties. Casting involves pouring molten metal into molds, while forging involves shaping heated metal through compression.

- Coating and Galvanizing: Coating and galvanizing are methods to protect steel from corrosion by applying layers of protective materials, such as zinc coatings. These processes extend the lifespan of steel products.

- Processing Centers: Processing centers handle various manufacturing operations such as cutting, bending, and welding to transform raw materials into finished steel products tailored to specific applications.

- Precision Machining: Precision machining involves using advanced tools and techniques to create intricate and highly accurate steel components for industries like aerospace, medical devices, and electronics.

- Recycling: Recycling plays a critical role in sustainable manufacturing by reclaiming steel scrap and repurposing it to produce new steel products, reducing the demand for virgin raw materials.

- Packaging: Steel is used in packaging applications due to its durability and strength. Steel packaging can range from cans for food and beverages to containers for industrial goods.

- Wire and Cable Production: This division involves the manufacturing of steel wires and cables used in various applications such as telecommunications, electrical wiring, and construction.

- Tool Manufacturing: Steel tools are essential for a wide range of industries, including construction, manufacturing, and maintenance. Tool manufacturing produces durable and high-performance tools for different applications.

- Fasteners and Hardware: Fasteners like nuts, bolts, and screws, along with various hardware components, are crucial for holding structures and products together. They find use in construction, automotive, and consumer goods.

- Automotive Components: Steel is a key material in the automotive industry, used in the production of components such as chassis, body panels, and engine parts.

- Consumer Goods: Steel is employed in manufacturing consumer goods such as appliances, furniture, and kitchenware due to its durability and aesthetic appeal.

- Energy and Infrastructure Applications: Steel plays a pivotal role in energy and infrastructure sectors, being used in pipelines, power transmission towers, and large-scale construction projects.

- Rail Manufacturing: Rails for railways are manufactured using steel due to its strength and durability, ensuring safe and reliable transportation systems.

- HVAC and Building Systems: Steel is utilized in heating, ventilation, and air conditioning (HVAC) systems, as well as various building systems, contributing to efficient and resilient construction.

GAO’s technologies enable its customers in “steel product manufacturing from purchased steel” to effectively track their workforces such as various job roles encompass steelworkers, metallurgists, plant operators, production supervisors, welders, machine operators, furnace operators, quality inspectors, crane operators, maintenance technicians, material handlers, logistics coordinators, process engineers, safety coordinators, research and development specialists, environmental specialists, designers/drafters, maintenance electricians, team leaders, and health and safety officers. Each role contributes unique skills to ensure efficient and safe operations within the manufacturing process. tively track operational assets such as an array of essential operational equipment is employed. These include rolling mills for shaping, furnaces for heating and melting, cutting and welding machines, CNC machining centers for precision work, cranes and hoists for heavy lifting, presses for forming, saws and lathes for cutting and shaping, as well as specialized equipment like blast furnaces, electric arc furnaces (EAF), basic oxygen furnaces (BOF), and continuous casting machines. Heat treatment furnaces modify properties, pickling and galvanizing lines provide surface treatments, and coating, painting, and testing equipment ensure quality. Material handling systems, sensors, and instrumentation facilitate smooth operations across the manufacturing process.

Here are some of the leading companies in steel product manufacturing from purchased steel industry GAO has served:

- Nucor Corporation

- United States Steel Corporation (U.S. Steel)

- ArcelorMittal USA

- AK Steel (now part of Cleveland-Cliffs Inc.)

- Gerdau Ameristeel

- NLMK USA

- SSAB Americas

- TMK Ipsco

- Steel Dynamics, Inc.

- Carpenter Technology Corporation

- Commercial Metals Company (CMC)

- Reliance Steel & Aluminum Co.

- Gulf Coast Steel, Inc.

- Bayou Steel Group

- California Steel Industries

- Kaiser Aluminum Corporation

- Portland Steel

- Hirschfeld Industries

- ArcelorMittal Dofasco

- Evraz Inc. NA Canada

- Stelco Holdings Inc.

- Algoma Steel Inc.

- Gerdau Long Steel North America

- Tenaris

- Novelis Canada

- Essar Steel Algoma (now Algoma Steel Inc.)

- Evraz Inc. NA

- Algoma Steel Inc.

- Tenaris

- Russel Metals Inc.

- Samuel, Son & Co., Limited

- Stelco Holdings Inc.

- Canam Group Inc.

- Russel Metals Inc.

- Gerdau Ameristeel Corporation (Gerdau Long Steel North America)

- Nucor Steel (Nucor Corporation)

- Précision Castparts Corp. (PCC Structurals Canada)

- Marmon/Keystone Canada Inc.

- Steelway Building Systems

- Atlas Tube (Zekelman Industries)

- Nova Tube Inc.

- Salit Steel

- AGF – Rebar Inc.

- Providence Steel and Iron Company

- CMC Rebar

- ADF Group Inc.

- Vestshell Inc.

You Are Invited to Contact Us!

If you are interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

or email us at sales@gaorfid.com